Africa has seen an increase in agricultural ingenuity in recent years. To combat the issues of climate change, scarce water resources, droughts, inarable land, expensive equipment, and producing food close to the markets, new approaches had to emerge.

One such approach, a tried, tested, and proven method of food production, is provided by Kleinskuur Aquaponics (KSBA). The agricultural industry has dabbled in hydro- and aquaponics for a couple of years now, but Kleinskuur Aquaponics adapted the technology to suit Africa and its specific needs as a developing continent. Kleinskuur Aquaponics is internationally recognised as a solution provider for food production on Africa.

The advantage of aquaponics supersedes traditional farming methods on every level. Because it is a circular system, water does not go to waste and all food production – including the fish – is 100% organically grown. Production is excellent and the quality of the food means people will get the healthy food they need.

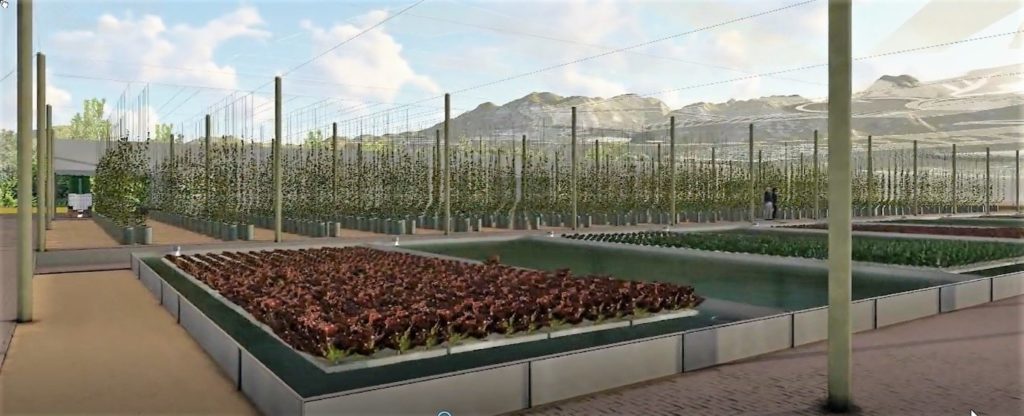

A system can be set up anywhere, in the desert, close to people, and in net houses to control the environment and manage the extreme weather conditions Africa has to offer.

Because the system is where the people are, jobs are created and there is an endless supply of a wide variety of crops from leafy vegetables to fruiting plants like tomatoes, brinjals, peppers and many more.

Solving the need for fruiting crops

Like any emerging method, aquaponics faces particular problems. The acclaimed UVI aquaponic system developed by the father of modern aquaponics, Dr James Rakocy, at the University of the Virgin Islands, works very well for leafy vegetables but makes no provision to produce fruiting vegetables. Murray Hallam from Australia resolved this problem by designing media beds filled with gravel in his famous CHOP and CHOP2 systems. Though these beds solved the problem of producing fruiting vegetables, a new set of challenges arose.

Farmers also experience problems with bell syphons traditionally built into media beds – roots clog up the system and it only works well when completely level. On top of that, if one plant in a gravel bed gets infected with a disease, all the plants need to be removed and the gravel needs to be cleaned.

The reason for the regular cleaning out of gravel beds is that small particles coming from the fish build up over time in areas where there is no water movement, which leads to the growth of anaerobic bacteria that can be disastrous in the system.

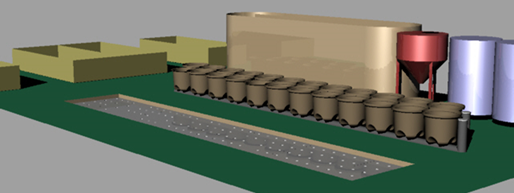

This is also a problem in the Dutch bucket design, a single plant growing system, normally used in hydroponics. The solution to these problems is the KSBA Gravel Barrel Auto Syphon™ system which was recently patented (RSA Pat. App. No. 2021/0879). The innovation was developed with the financial assistance of the Technological Innovation Agency (TIA) where it also received recognition in 2021 as one of their top female driven innovations.

This is how it works:

This robust, cost-effective bucket is made from UV resistant materials and is big enough (35 litres) for large vine-type plants, yet small enough to be handled by one person, male or female. The barrel has no moving parts and since the syphoning system is not part of the bucket, the roots of plants cannot clog up the syphon.

The shape of the barrel prevents the growth of anaerobic bacteria, because all the water gets drawn out through the bottom, while sucking air in from the top. The sets of barrels have to be used with the specially developed outflow pipes and auto syphons.

The sets can also be used in hydroponic systems. The water will flow from the dosing tanks into the barrels, and can be directed from the auto syphons into a channel or pipe going to a sump.

Because one barrel holds one plant, it gives the farmer freedom to produce a large variety of fruiting plants.

The Kleinskuur Gravel Barrel Auto Syphon™ system enables commercial and small-scale farmers to produce fruiting crops and the barrels are used in the KSBA Family Systems, Community Systems, and large Commercial Systems.

Sets of Gravel Barrels

Kleinskuur Aquaponics provides from 6 to 26 barrels per set. Farmers can choose if they want double rows with a looped inlet pipe or single rows.

Kleinskuur offers a range of systems to suit the needs of the farmer. The systems are named after the number of gravel barrels in the system. So, the KSBA24 Family System, ideal for a household and friends, offers 24 barrels and the KSBA4000 Commercial System has space for 4000 fruiting crops.